Fullyguide has over 18 years of experience in injection molding, finishing, and assembly work in every conceivable product category including Automotive, Electronics, Aerospace, Medical, and Telecommunications.

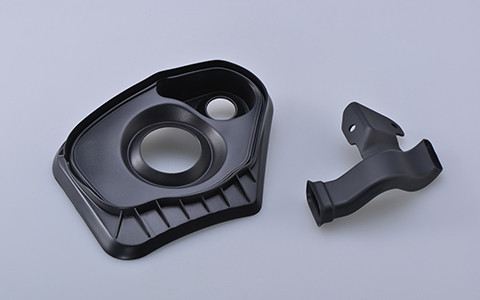

Fullyguide can offer a complete service for components and sub-assemblies manufactured in engineering polymers, all on the one site. Secondary operations include inserting, painting, printing, hot staking, ultrasonic welding, chrome plating, and Vacuum metallization. We have many years of experience in producing top-quality parts in all general and most engineering thermoplastic polymers including Ultem, PEEK and specially compounded polymers for conductivity and RF screening and other specialized requirements.

Our range of equipment includes 40 injection moulding machines ranging from 50T to 650T clamping force and 20 machines with full robotics. This allows us the flexibility to manage both small volume and high-volume production batch sizes in the most efficient manner.