What is 5 Axis CNC Machining?

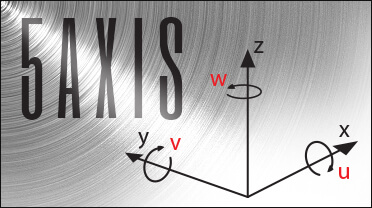

5 axis machining is unique in its ability to effectively process part sizes and shapes with essentially infinite possibilities. Like 3 axis machines, the cutting tool of a 5 axis machining center moves across the X, Y, and Z linear axes, but also rotates on the A and B axes – allowing the cutting tool to approach components from any direction. An experienced machinist can achieve incredibly complicated geometries with high precision when using all 5 axes in conjunction. The skilled and highly experienced CNC machinists and programmers at Fullyguide are capable of machining complex shapes, undercuts, and complicated angles – all in one setup to boot.

The ability to machine a component to completion in a single setup not only adds to the precision achieved during machining but also reduces tooling costs, overhead costs, and labor time, resulting in the lowest possible cost per part. 5 axis machining centers eliminate several inadequacies of conventional CNC machining techniques, including multiple setups, part transfers, and inspections; part handling, and errors associated with human involvement/interference.

5 axis machining is used across a number of industries to produce precision dependent components with fast manufacturing times and repeatable accuracy, including:

- Military Satellites

- Aircrafts

- Aerospace

- Optical Equipment

- Medical Devices

- Tools & Dies

Fullyguide serves these industries and more, consistently exceeding industry quality standards and the capabilities of normal CNC machine shops. We are happy to take on prototype or production machining work.